Choosing chemical protection clothing is becoming more difficult every day due to the ever-increasing variety of types and brands. However, there are a number of basic considerations that you should take into account.

Do you work with chemicals? In which case, a good chemical protection suit is essential for protecting your skin from harmful chemical splashes.

Here we list the main points for you to consider:

- The nature of chemical risk

- The difference between permeation and penetration

- Mechanical strength

- Disposable or -limited- reusable chemical suits: Which is the best choice?

- Clothing options

- Follow the correct donning and doffing procedure

Discover our chemical clothing

1. The nature of chemical risk

Before you begin selecting your chemical protective clothing, you should carry out a risk assessment to understand which specific hazards/risks you need to be protected from. Identify the chemicals you are working with and identify their chemical properties, such as corrosivity, toxicity and flammability. By understanding the risks, you can determine the appropriate levels of protection.

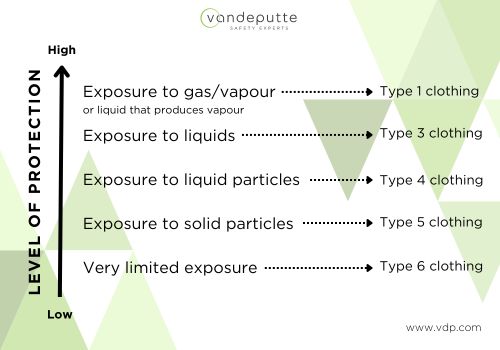

The state or form of chemical hazard will determine the appropriate type of clothing required:

Types 3, 4 and 6 give you the additional option of protecting a part of the body (Partial Body protection), depending on which area of the body.

European standards

Type 1: Gas-tight suits (EN 943-1 & 2)

Gas-tight suits provide the highest protection against highly toxic gases and vapours. They are available in different variants:

- EN 943-1 - Type 1a: Compressed air worn inside the suit

- EN 943-1 - Type 1b: Compressed air worn outside the suit

- EN 943-1 - Type 1c: With compressed air supply

- EN 943-2: For emergency teams

Type 3: Liquid-tight suits (EN 14605)

These suits protect against powerful and directed jets of toxic, non-volatile liquids. They are ideal for interventions or for maintenance to pressurised pipes. Liquid tightness is established by the jet spray test.

Type 4: Spray-tight clothing (EN 14605)

Spray-tight overalls protect the entire body from spray from non-volatile toxic liquids. They are suitable for paint spraying and industrial and agricultural applications. Spray density is established by a spray test.

Type 5: Dust-tight clothing (EN ISO 13982-1)

This clothing protects against toxic airborne solid particles and is ideal for demolition, mining and dusty industrial and agricultural applications. A less stringent spray test establishes the dust tightness.

Type 6: Low volume liquid chemical protective clothing (EN 13034)

This clothing provides protection against chemical splashes, and is suitable for industrial and agricultural applications and woodworking. An aerosol test establishes the density. Type 6 uses uncoated material, such as a fabric lab coat, while types 1 to 4 have a coating.

Clothing information should be stated on the garment label.

2. The difference between permeation and penetration

When choosing a chemical suit, it is important to assess the hazards of both permeation and penetration. The permeation process is invisible, but no less dangerous. Good penetration protection is more important when you come into direct contact with chemical fluids.

Permeation: Permeation is the process by which a chemical penetrates through the material of the suit at the molecular level. By correctly interpreting the breakthrough times and the toxicity of the chemical, you are able to choose the right suit to achieve adequate protection for working safely. Workwear is tested according to ISO 6530.

Penetration: Penetration is the movement of a chemical through holes, tears or seams of a chemical suit, above the molecular level. Pay special attention to how the suit fits your body, especially when worn in combination with other personal protective equipment. Also check the quality of the suit: Are all seams sufficiently reinforced, is the material abrasion resistant, and can all zips be properly taped?

- EN 13034-6: Protection against small splashes or light spray from chemical liquids.

- EN 14605 (type 4): Resistance to penetration of liquids under pressure.

- EN 14786: Resistance to ingress of spraying liquid chemicals.

Important considerations:

- Know the nature of the contaminant: Know what harmful chemicals you're dealing with.

- Do not extrapolate results: Types of PVC, Neoprene or Butyl can vary. Results from one substance cannot simply be applied to another.

- Use reference substances: The 15 substances from the EN943-2 standard have been chosen as reference substances because they cover a wide range of substances. These substances serve as an excellent guide in choosing the appropriate protective clothing.

3. Mechanical strength

When the mechanical risk is high, the clothing can be evaluated based on the following:

- Abrasion resistance (EN530): The material is rubbed against abrasive paper under pressure.

- Flexing resistance (ISO7854): The material is compressed and checked for holes and perforations.

- Tear resistance (ISO 9073-4): A cut in the material is pulled apart to measure the tearing force.

- Tensile strength (ISO13934-1): A 50 mm wide piece of material is pulled apart to measure the elongation force.

- Perforation resistance (EN 863): A steel tip is pushed through the material to measure the penetration force.

- Flame resistance (EN13274-4): The material must be self-extinguishing and must not burn for more than 5 seconds after the flame has been removed.

- Seam strength (ISO 13935-2): The strength of different seam structures is tested; the lowest score determines the class.

4. Disposable or -limited- reusable chemical suits: Which is the best choice?

Is it better to choose a suit that can be discarded after use, or one that is reusable? We have made a list of the pros and cons for both types.

- Disposable: Disposable clothing should be discarded immediately after use. The typical service life of these suits is five years. Since 2015, the service life has been extended to ten years, provided that a pressure test is carried out after seven years.

- Limited Reusable: Limited reusable clothing can be reused if not contaminated. The suit can be reused following a pressure test. If the suit has been contaminated, it must be discarded. The typical service life is ten years, with no testing in the first five years, and annual testing over the following five years.

- Reusable: Reusable clothing can be used several times, provided it is decontaminated and retested. The service life of these suits varies between seven and ten years.

| Criteria | Disposable | Reusable |

|---|---|---|

| Decontamination | +++ | -- |

| Comfort (weight) | - | --- |

| Maintenance | +++ | - |

| Mechanical | ++ | +++ |

| Permeation | +++ | ++ |

| Cost | ++ | - |

Much depends on your working conditions, personal preference and budget.

However, the same applies to every chemical suit, whether reusable or not, and that is if it is damaged or contaminated, it cannot be reused. Disposal, or meticulous cleaning and repair will be the only solution.

Discover our chemical clothing

Lakeland and Respirex have developed an app that, as a wearer, gives you the option to determine the safe wearing duration of a chemical garment. How to use the Permasure® app is shown in the video below.

5. Clothing options

When choosing protective clothing, both disposable and reusable, there are several options available to adapt the clothing to specific needs and to combine these with other personal protective equipment (PPE).

- Cuffs and gloves

- Leg ends and boot systems

- Hood options

- Attachments for lamps, lifelines and other accessories

- Ventilation and fall protection

6. Follow the correct donning and doffing procedure

Donning, and especially doffing a chemical disposable suit is crucial for protection in chemical applications. And far more so when it comes to protecting against infectious organisms (EN 14126). Contamination must be avoided at all times.

Write a procedure for this and, if necessary, provide a ‘donning and doffing’ training course for your employees.

This video can help you with this:

Conclusion

Step 1: Choose the type of clothing according to the state/nature of the chemical substance

Step 2: Select the correct clothing construction material within the type, based on permeation data

Step 3: Choose a garment with the correct mechanical resistance

Step 4: Choose either disposable or reusable

Step 5: Choose different options

Step 6: Follow the correct donning and doffing procedure