Last update: 08/09/2023

If your employees work near heat or naked flames, they must wear protective clothing. Clothing that fulfils the EN ISO 11612 standard protects the wearer against heat and flames and is also flame-retardant.

What is EN ISO 11612

When choosing clothing for protection against heat and flames, you will encounter European standard EN ISO 11612. Clothing which is certified according to this standard offers employees the protection that they need during work.

The standard also offers design requirements for this clothing in order to guarantee the safety of the wearer. The EN ISO 11612 standard does not apply to clothing for professional fire-fighters or welders.

Download the information sheet

Marking

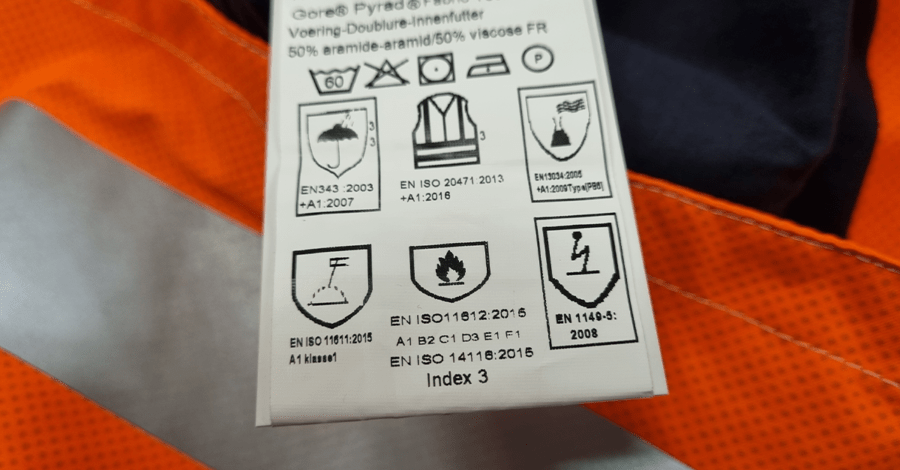

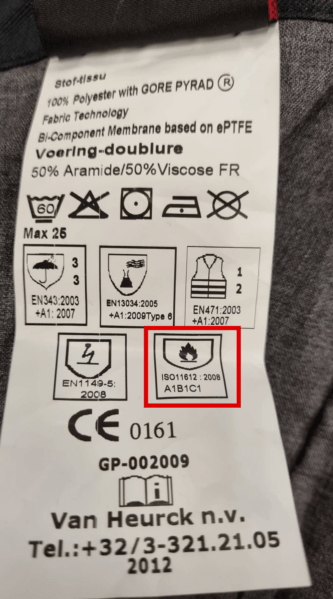

The EN ISO 11612 standard contains 6 criteria on which protective clothing must be tested. The results of these 6 tests have a letter from A to F and a number. The number represents the performance level of the materials.

You will find these letters and the number on the label of your flame-retardant clothing, under the official icon (shield with a flame).

EN ISO 11612: 6 tests

A - Flame spread

This is the only mandatory test for EN ISO 11612. Additionally, at least 1 of the other tests must be carried out. Which test this is depends on the activities for which the fire-retardant clothing will be used.

The test material is first washed and then tested. It is washed for the number of times given as the maximum number of washes by the manufacturer.

The requirements for a successful flame spread test are:

- no holes created

- no afterglow

- no falling drips

- no burning at the edges

Performance levels

- A1: flame spread on surface

- A2: flame spread at edges

B - Convection heat

This test determines the heat conduction when clothing comes into contact with flames. A calorimeter measures the temperature increase on the upper side of the clothing when this is held above a flame.

The test indicates how many seconds it takes for the temperature to increase by 24°C.

Performance levels

- B1: 4 to 10 seconds

- B2: 10 to 20 seconds

- B3: more than 20 seconds

C- Radiated heat

During this test, an infrared heat source is used to find out how resistant the clothing is to radiated heat.

It is a measurement of how long it takes for the temperature of the test material to increase by 24°C. Various outcomes are possible.

Performance levels

- C1: 7 to 20 seconds

- C2: 20 to 50 seconds

- C3: 50 to 95 seconds

- C4: more than 95 seconds

D - Molten aluminium

This test examines how many grams of molten aluminium are blocked by the protective clothing.

The performance level indicates how many grams can be applied while maintaining undamaged artificial skin underneath.

Performance levels

- D1: 100 to 200 grams

- D2: 200 to 350 grams

- D3: more than 350 grams

E - Liquid iron

Liquid iron can severely damage the skin.

This test determines the maximum quantity of molten iron that can be poured onto the material while the skin underneath remains undamaged.

Performance levels

- E1: 60 to 120 grams

- E2: 120 to 200 grams

- E3: more than 200 grams

F - Contact heat

This test examines how many seconds it takes for the temperature behind the test material to increase by 10°C.

The heat source has a temperature of 250°C.

Performance levels

- F1: 5 to 10 seconds

- F2: 10 to 15 seconds

- F3: more than 15 seconds

For example: EN ISO 11612 A1 A2 B1 C1 F1

In this example, you can see that a fire-retardant item of clothing is successful in the following tests:

- Flame spread, both on the surface and on the edges of the fabric

- Convection heat with a performance level of B1 (4 to 10 seconds)

- Radiated heat with a performance level of C1 (7 to 20 seconds)

- Contact heat with a performance level of F1 (5 to 10 seconds)

The tests on molten aluminium and liquid iron were not conducted.

Info sheet EN ISO 11612

Need a visual summary of this standard? Download our free information sheet.